Wine and mash preparation

RAW MATERIAL TREATMENT

Preparation of fruit wine as vinegar substrate

The fruit is washed, peeled and put into the fruit milling cutter where it is cut to the optimum particle size according to the kind of fruit.

The resulting fruit juice is put into fermenters, where the alcoholic fermentation into fruit wine takes place under addition of enzymes (for pectine reduction) and yeast. After separation of the yeast and solids, the fruit wine is ready for mash preparation.

Mash preparation

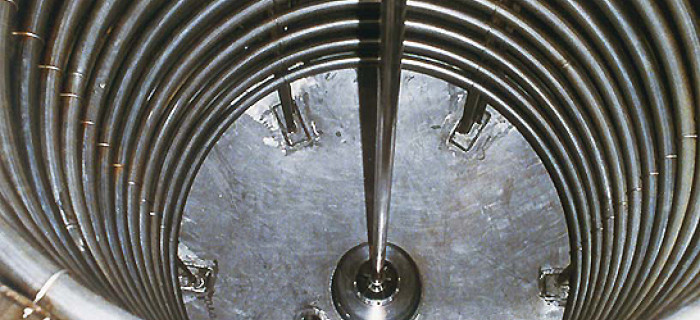

The fermentation substrate (wine) must have an ethanol content in the range of 5 to around 15 %. It is mixed with raw vinegar containing acetic acid bacteria in the injection tank. Nutrients and some vinegar are blended in the nutrient vessel, then added to the injection tank and mixed to dilute.

This mash preparation is carried out in batches once or twice a week in one of the injection tanks while the other is used as feed tank for the fermentation.